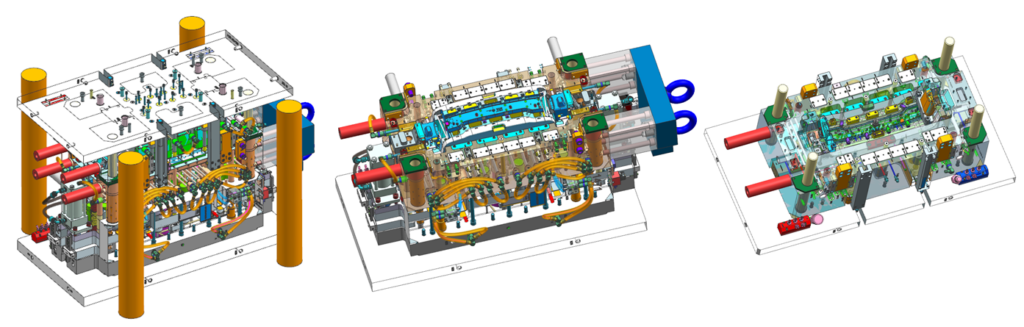

Mold Design

Our mold design team is experienced and skilled with 10+ years knowledge in global mold design for European, North American, Asian etc. Our senior designers are capable of reading customers standards and special requirements in English. Professional detailed mold design is key for a superior mold.

- Mold design can follow with customers special requirement or normal global mold design standards, such as DME/Meusburger/HASCO/ Progressive/MISUMI etc.

- The 3D mold design formats can any types that customers want, for example: STEP/IGES/Parasolid/Catia/Solidworks etc.

- Mold design is 100% completed with details and checked during mold design review meetings before sent to customers.

- For complex molds, we can also do a mold motion simulation analysis to prove the feasibility of comprehensive mold structure. In the simulation, we can vividly see the mold movements from open to close, step by step.

DFM

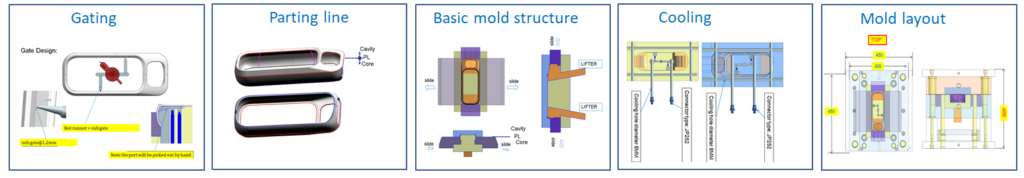

We make professional DFM study for all of our molds and submit detailed DFM to customers to get customers comments. Our normal DFM study contains items below:

- Basic Project and product information(part No./ name/ steel material and resin material/ injection machine spec etc.)

- Injection system with detial pictures of gating for the part

- Main mold layout(showing dimesion of the mold)

- Product main parting lines and split lines of inserts

- Draft angle analysis and product thickness study

- Ejection layout and concept

- Cooling sketch layout

- Product surface finish review

- Part and steel tolerance review

- Any other customers requirements would be also included in our DFM

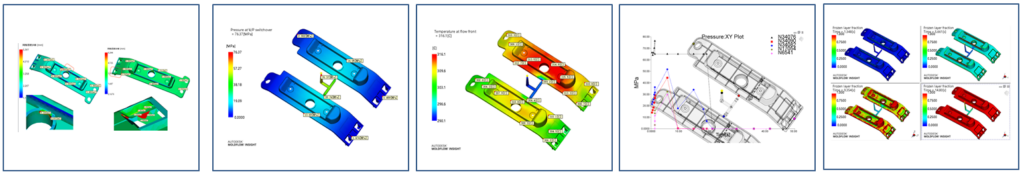

MoldFlow study

We apply practical MoldFlow study for mass prodution molds to keep good quality and avoid any potential defects/risks in advance. We make a full analysis: Filling>>Packing>>Warpage>>Cooling

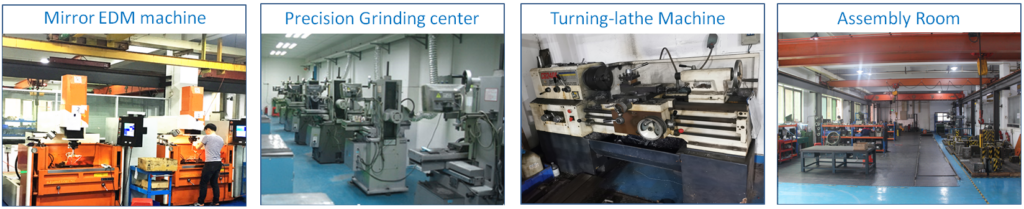

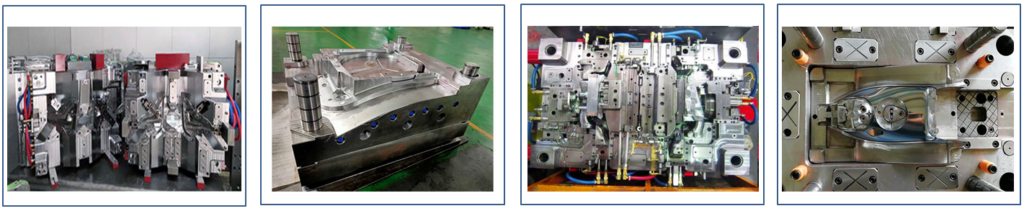

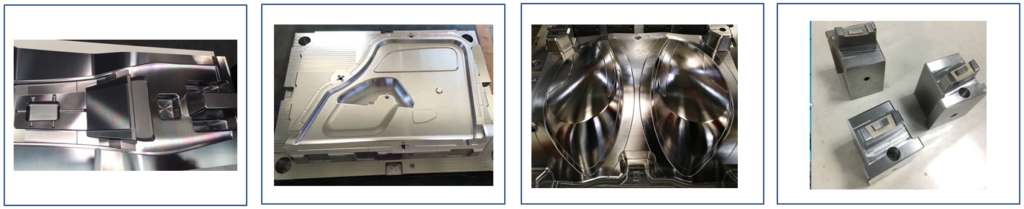

Mold Making

We are professional mold-making factory, dating from 2011. Mold-making is our main business, occupied 90% and 10% for injection production. We are fully equipped with advanced CNC/EDM/grinding/CMM machines and etc. Over the past years, we have built many complex and precision molds for automotive/equipment appliance/medical etc.